Case Studies

The collaboration between the Innoptus Solar Team and Virtek shows how advanced technology can solve challenges in high‑pressure environments. With tight timelines and the need for precise composite layups, the team used Virtek IRIS™ 3D to streamline production, saving time and improving accuracy. Its fast integration and ease of use helped them shift quickly from manual processes to a digital workflow.

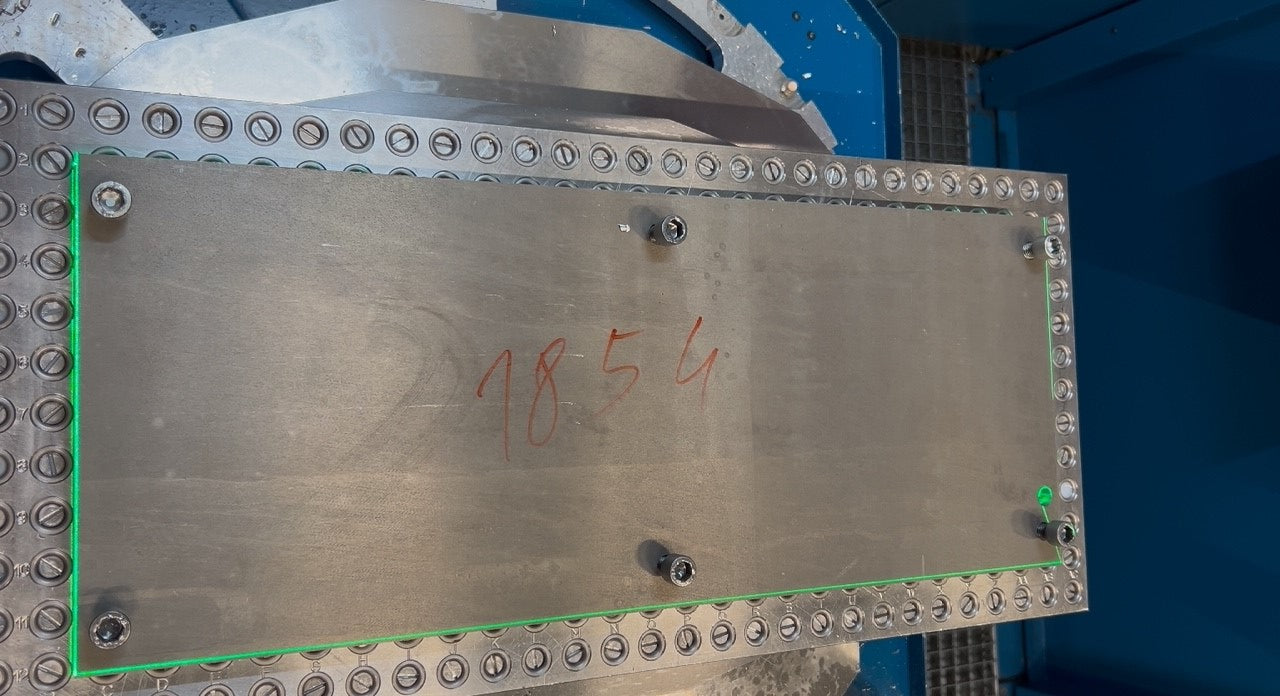

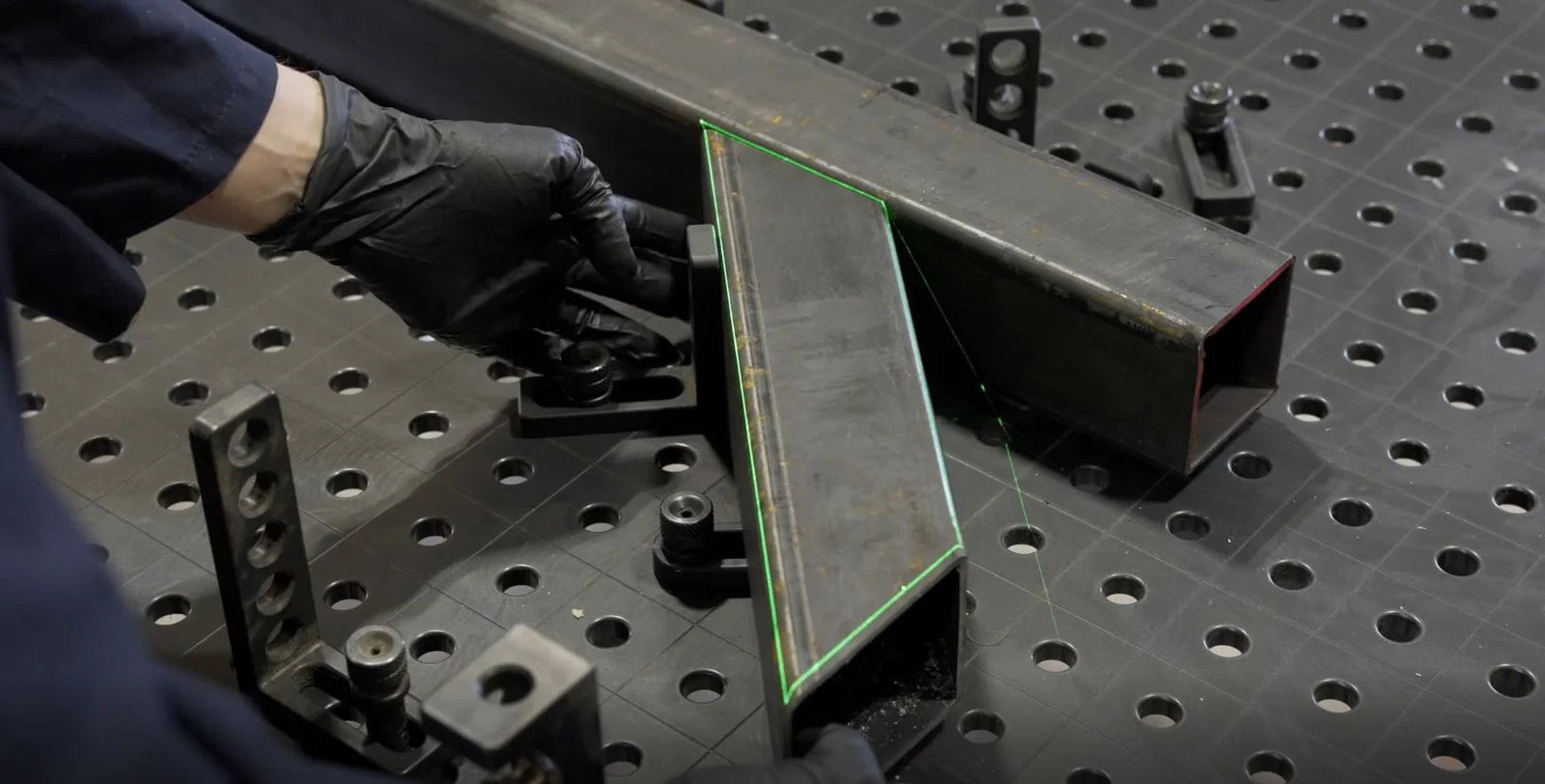

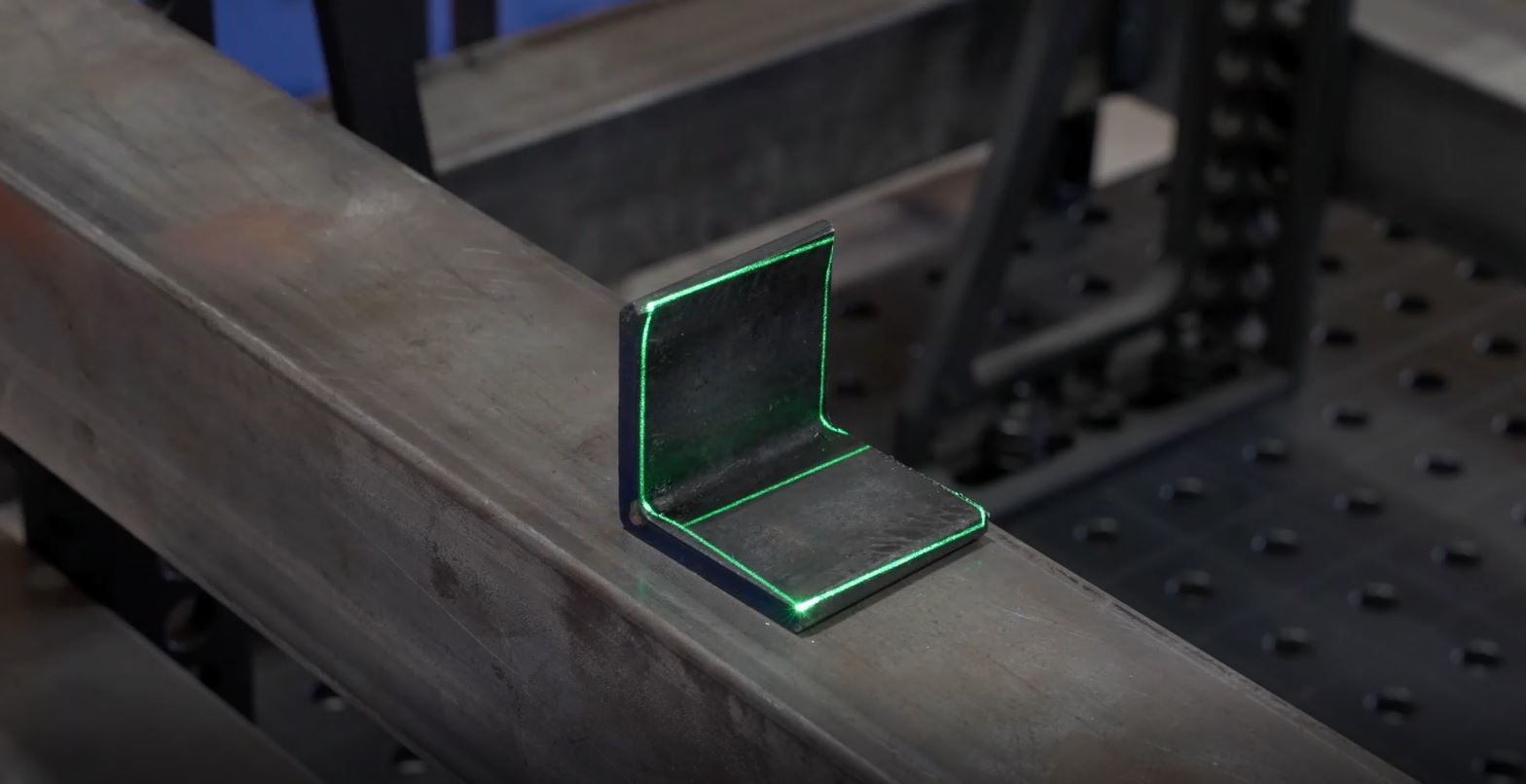

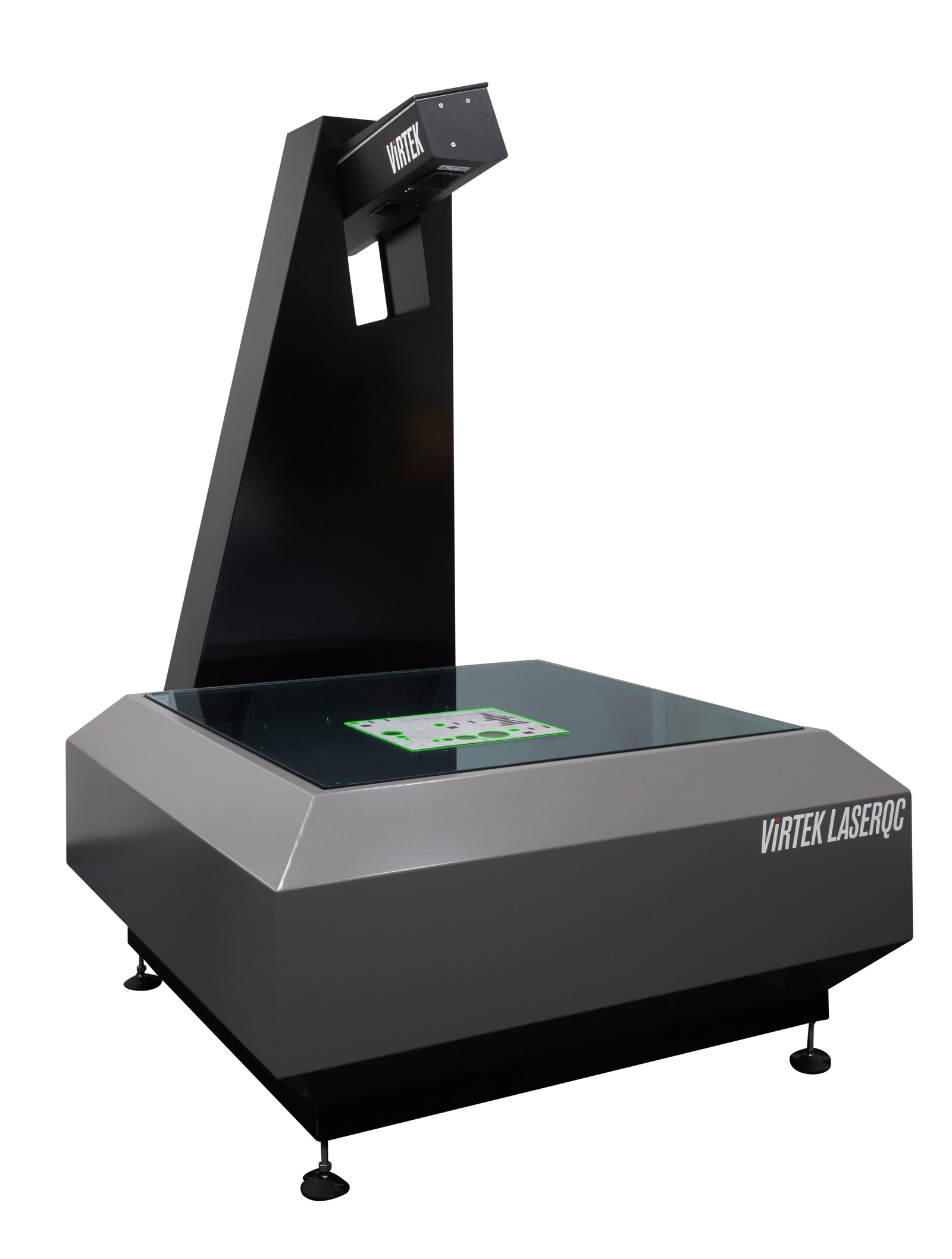

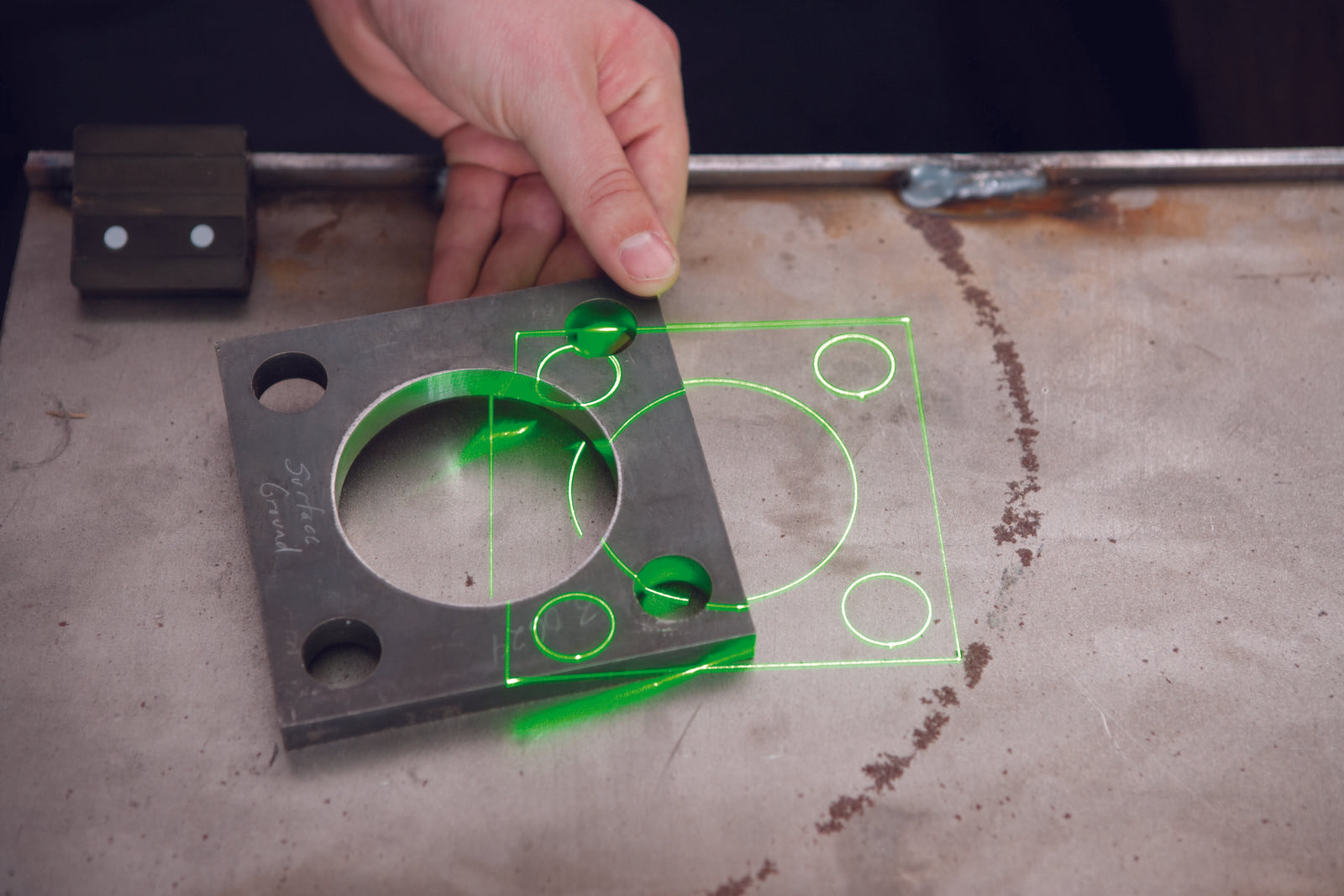

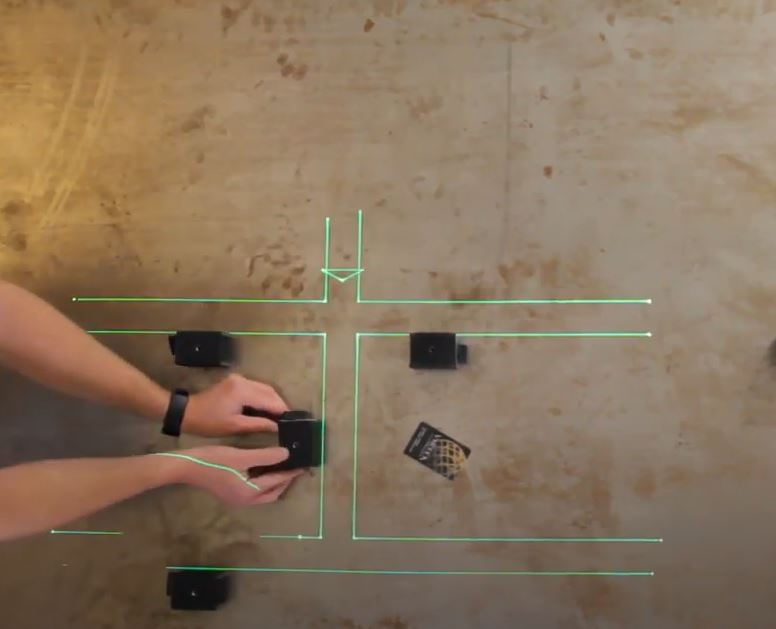

By implementing Virtek’s LTG system, Metalcrafters of Wayne County, Inc. has transformed its fabrication processes, saving time, improving accuracy, and addressing bottlenecks caused by traditional layout methods. Beyond fabrication, the LTG system’s value as a QC tool ensures that every part meets exact standards, reinforcing Metalcrafters’ reputation for

delivering high-quality metalwork.

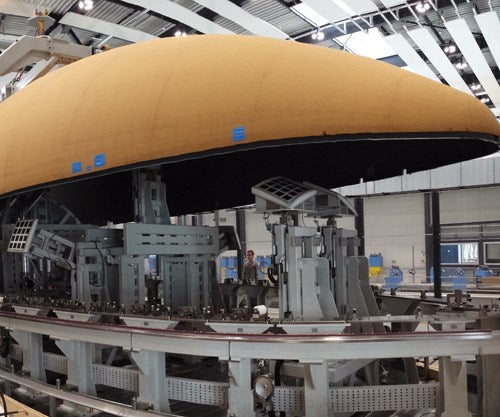

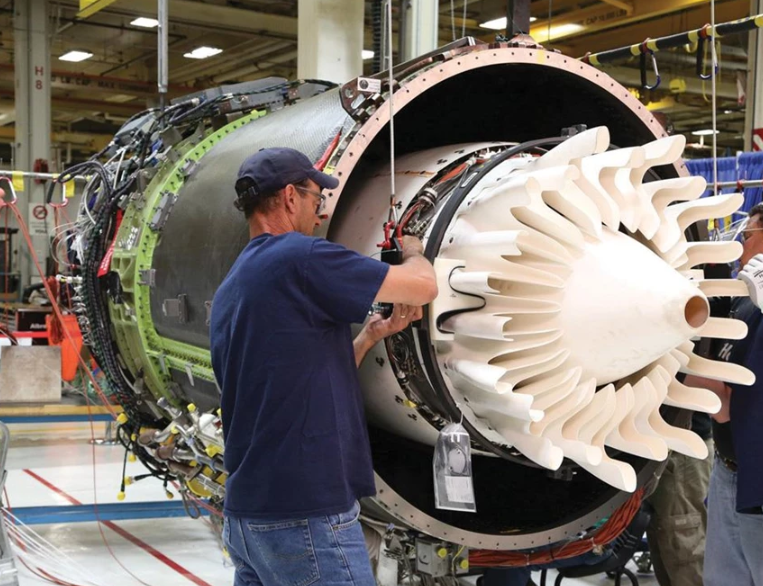

Pilatus’s decision to implement Virtek’s IRIS 3D software with Vision Positioning System (VPS) has delivered significant improvements in their manufacturing process. While the installation presented some challenges, the long-term benefits—such as increased productivity, higher process security, and precise part positioning—have made a clear impact on their operations. By integrating Virtek’s technology with their existing systems, Pilatus has successfully optimized their production line, driving efficiency and enhancing overall quality control in an increasingly complex manufacturing environment.

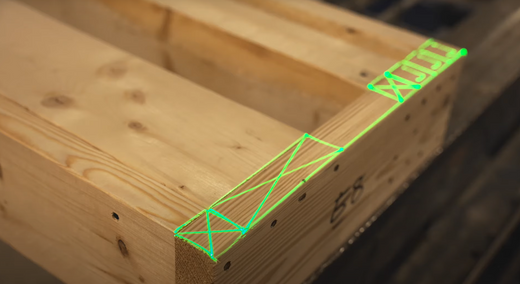

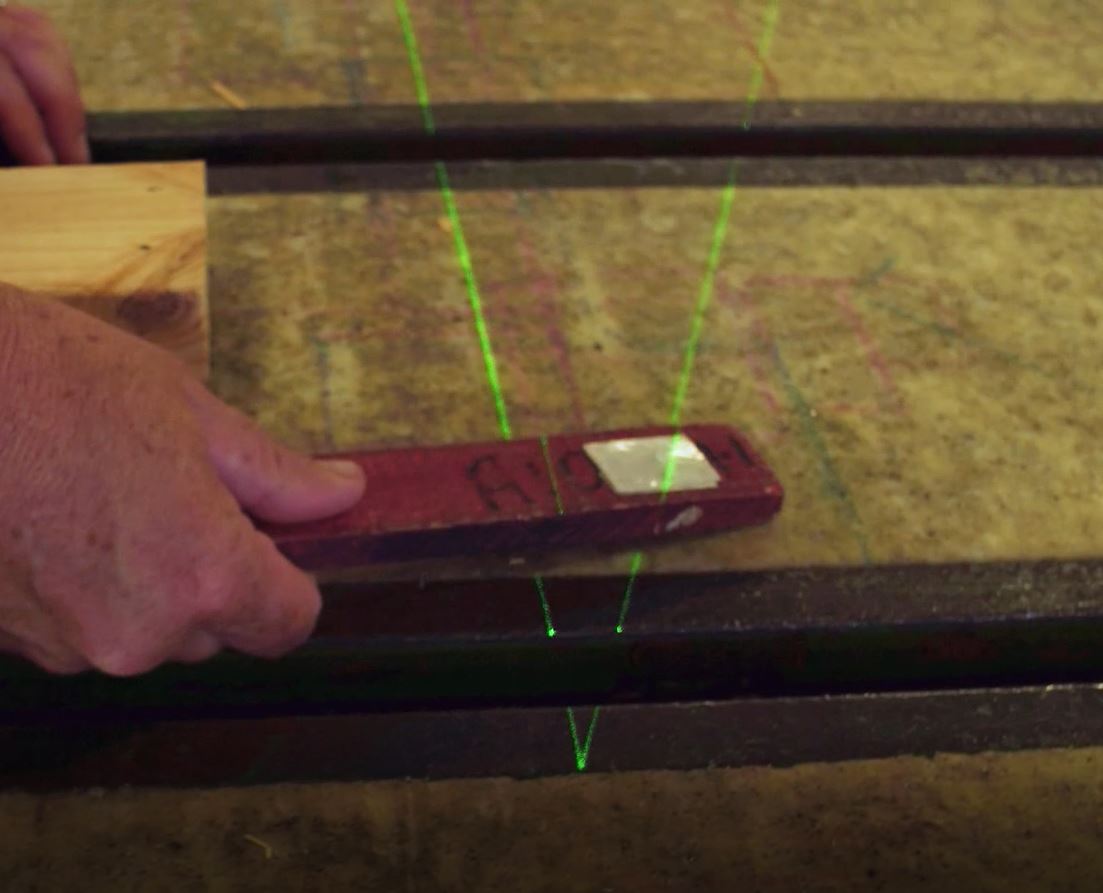

Since integrating Virtek’s laser systems, TRS has experienced a remarkable 65% increase in efficiency in their building components production.