Case Studies

Century mentioned it can take several hours for an employee to inspect parts manually, with the Virtek LaserQC, it takes only a minute or two.

Salem was able to reverse engineer the part and make it while customers toured the shop and have it ready for them by the time they were ready to leave.

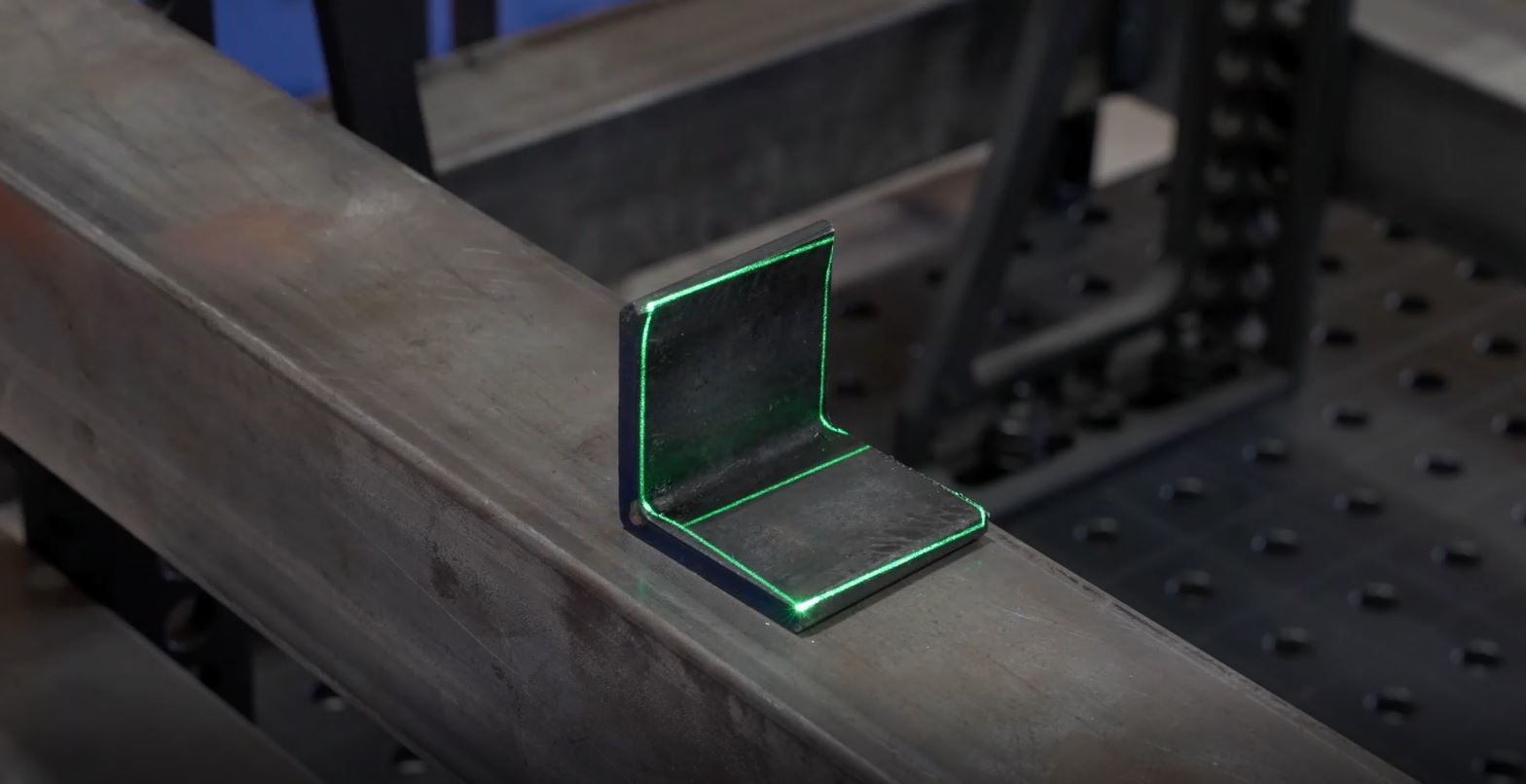

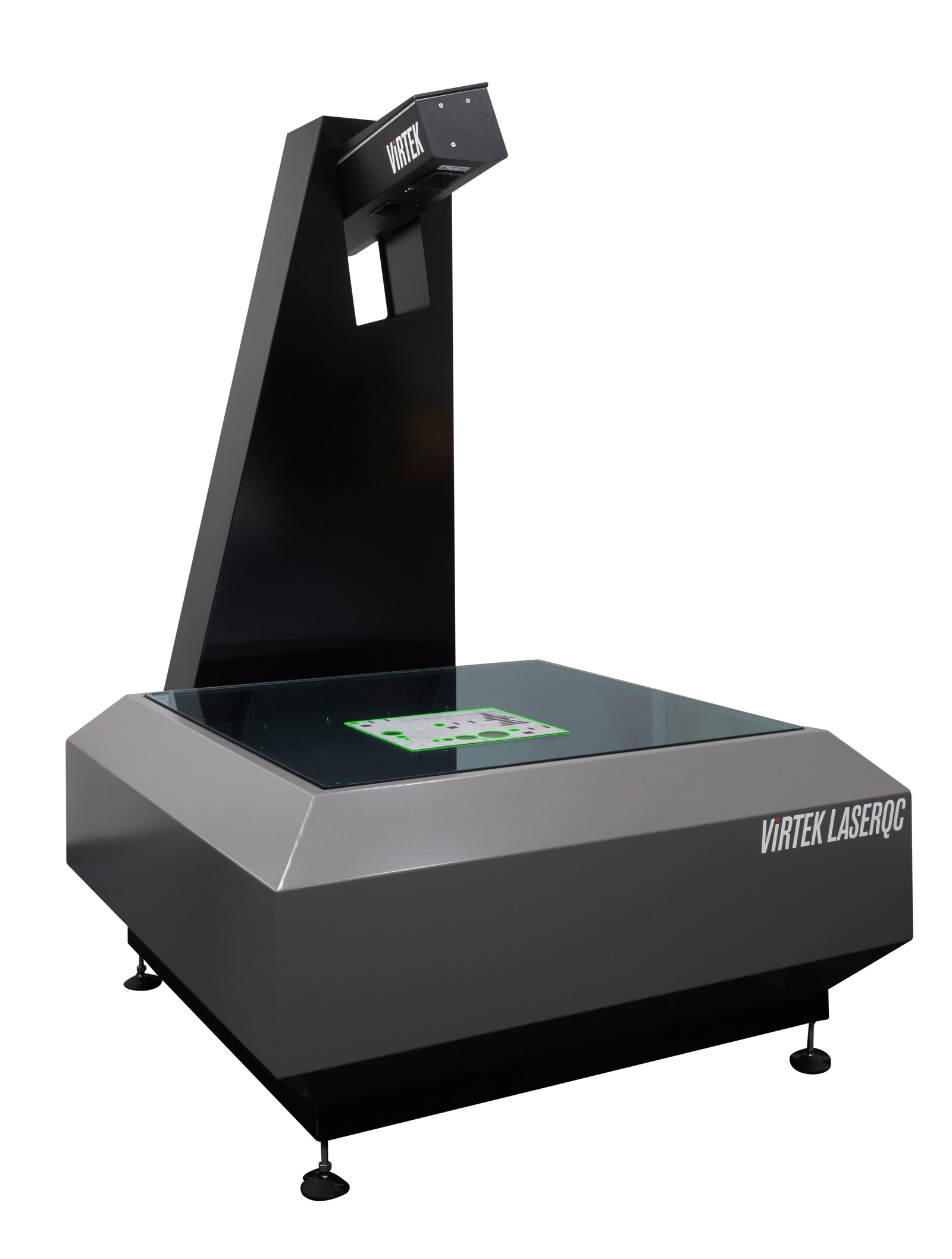

In manufacturing, every step in the production process is an opportunity to save time and money. Precisely projecting a beam of laser light onto surfaces, laser projection technology efficiently guides manufacturing operations, saving money in applications such as assembly, templating and inspection.

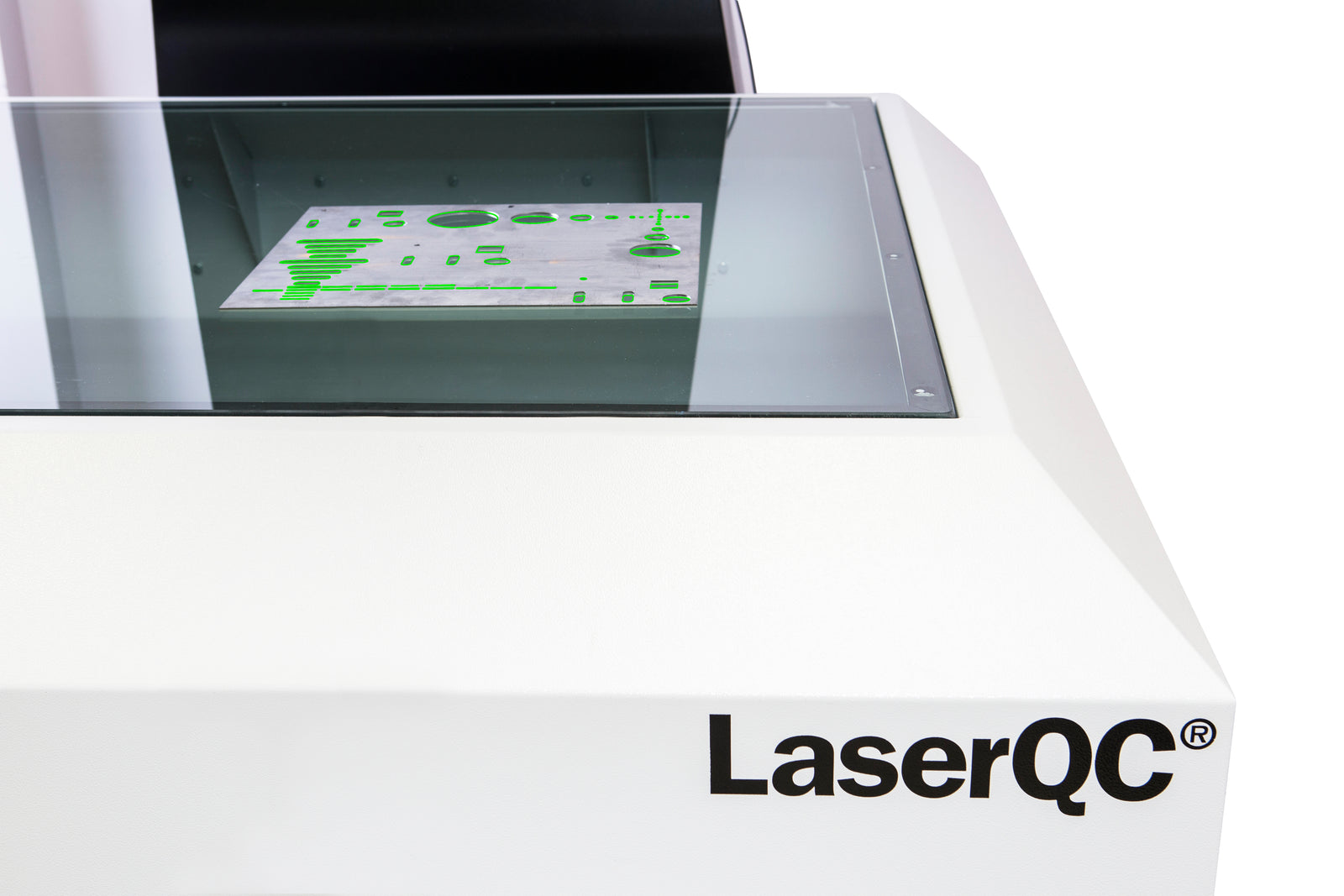

Trilux chose Virtek LaserQC® to modernize its measurement process, leading to improved speed, quality and customer satisfaction.