Case Studies

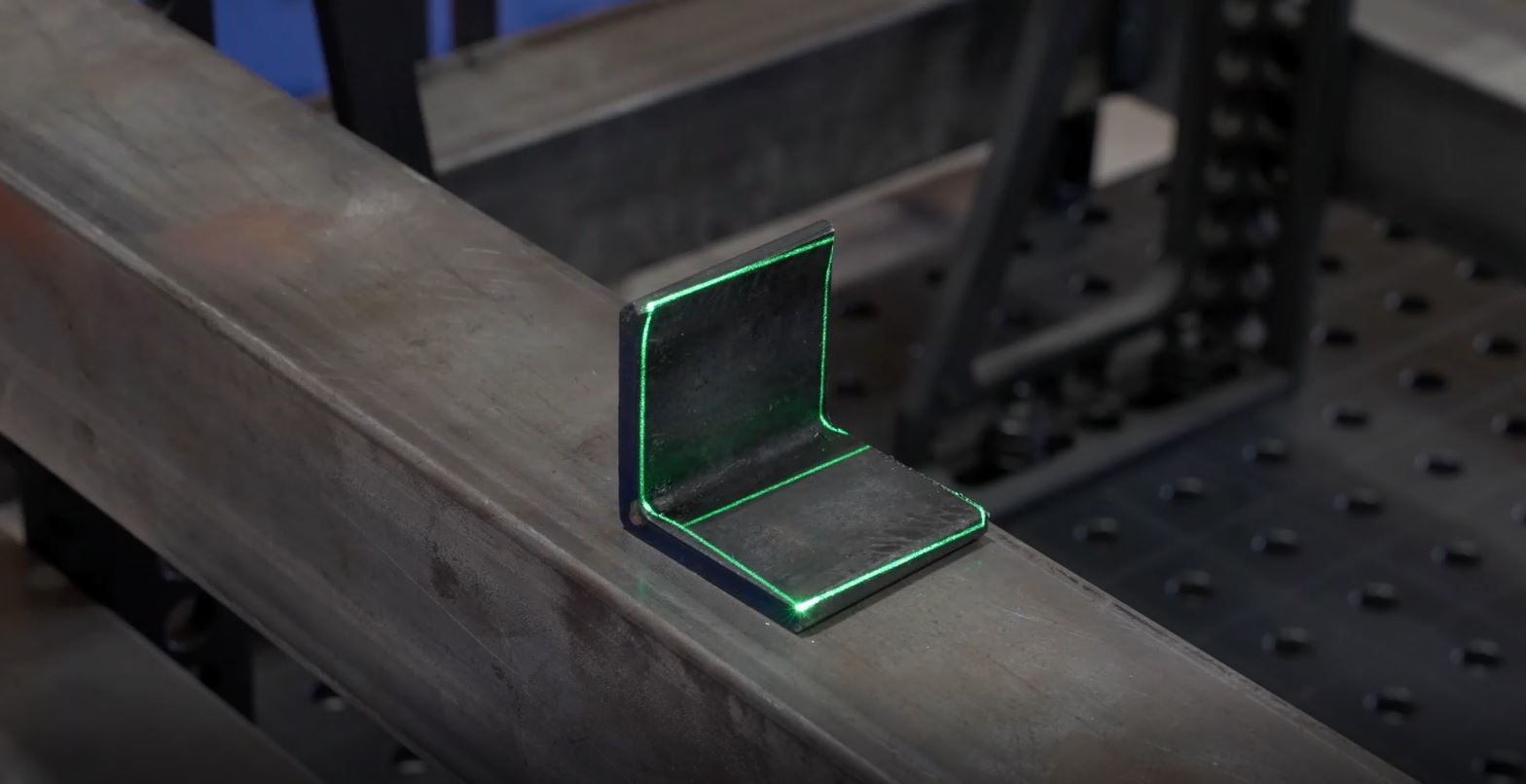

By implementing Virtek’s LTG system, Metalcrafters of Wayne County, Inc. has transformed its fabrication processes, saving time, improving accuracy, and addressing bottlenecks caused by traditional layout methods. Beyond fabrication, the LTG system’s value as a QC tool ensures that every part meets exact standards, reinforcing Metalcrafters’ reputation for

delivering high-quality metalwork.

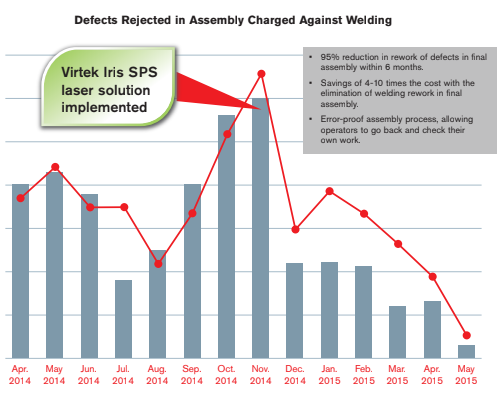

Komatsu was able to eliminate the use of templates, manual measuring, marking and fitting steps and was able to error proof the assembly process.

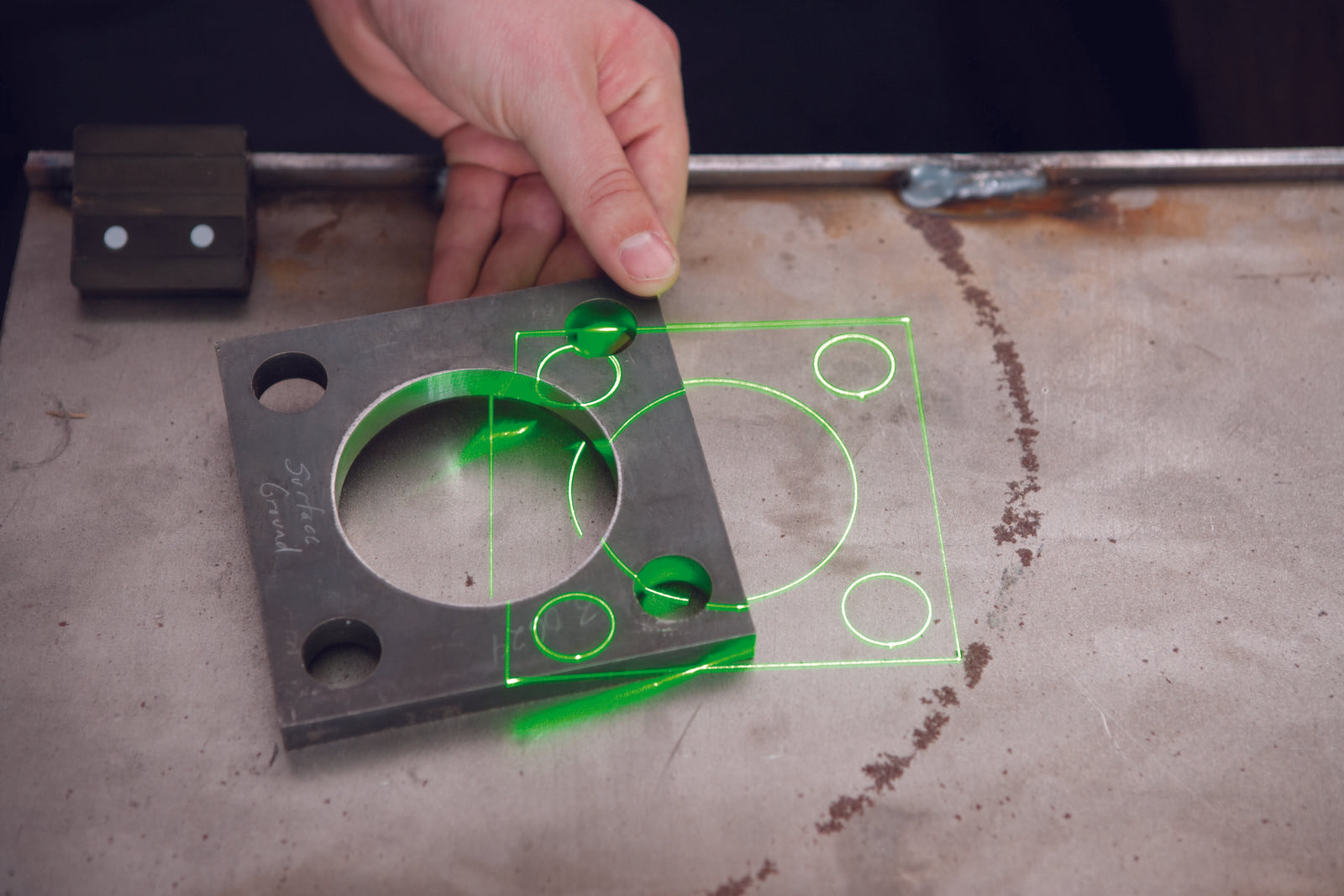

In manufacturing, every step in the production process is an opportunity to save time and money. Precisely projecting a beam of laser light onto surfaces, laser projection technology efficiently guides manufacturing operations, saving money in applications such as assembly, templating and inspection.

Weldall reduced setup times from 6 or 7 hours to 1.5 hours on some parts and achieve 100% accuracy.

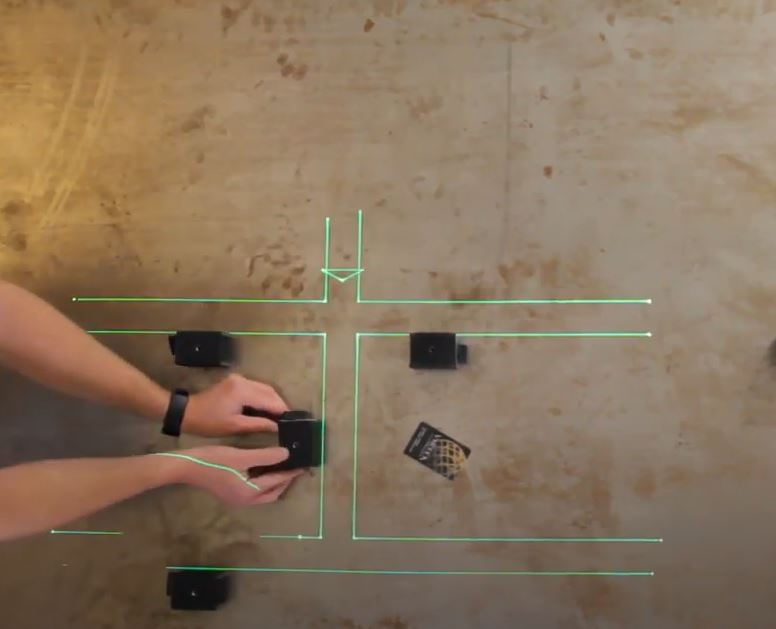

XOVR's Layout Handrail System uses Virtek's Laser Projection, and for Assembly Manufacturing of Wall Panels up to 5X faster layout!