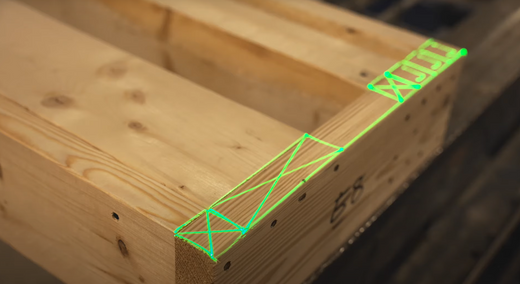

Since integrating Virtek’s laser systems, TRS Components has experienced a remarkable 65% increase in efficiency in their building components production. This cutting-edge laser technology enables precise measurements and accelerates assembly processes, ensuring that each component meets exacting specifications. The TRS team leverages the system to accurately position studs and blocking in wall panels, a critical step that not only speeds up production but also minimizes errors.

TRS is always looking for ways to enhance their processes

and deliver even greater value to their customers. As part

of this commitment, they sought to improve the efficiency

and accuracy of producing complex roof & floor trusses

and wall panels. These components require intricate

designs and precise measurements, and TRS recognized

the opportunities to optimize their production workflows by

addressing manual efforts, accuracy and cycle times to

help them meet the growing demand for high-quality

building components.