News

News

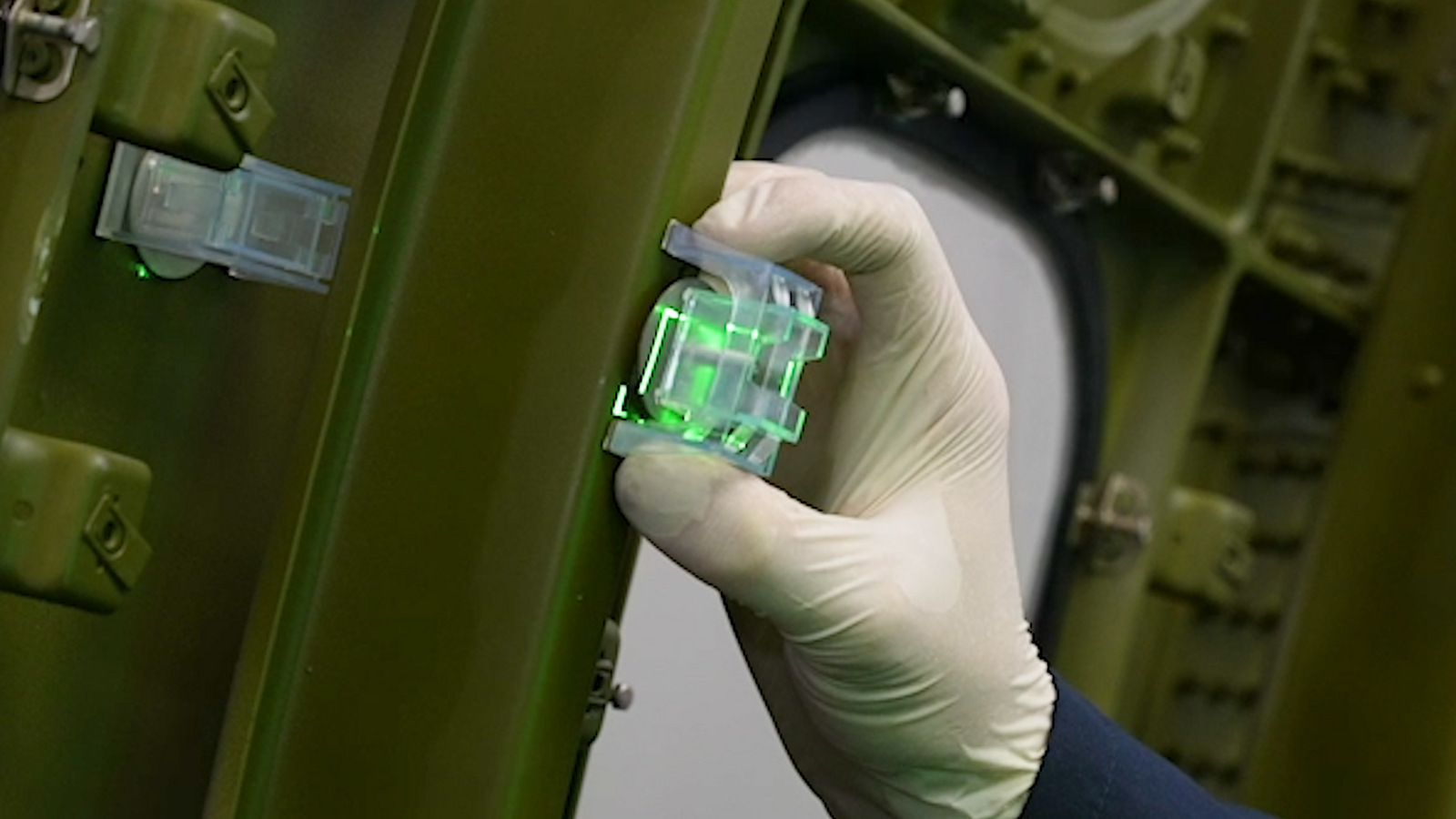

The Virtek Ai Camera system integrates with laser projection systems for Foreign Object Debris (FOD) detection, particularly focusing on ply backing and other generic FOD. See more at CAMX24 in San Diego, Booth #MM33

Virtek Vision Int’l., technology supplier to many of the world’s top-tier aerospace and composite manufacturers, will demonstrate its next generation Iris 3D Process Monitoring Software, integrated with its new artificial intelligence (AI)-enabled camera system, during JEC World 2024.

In a Q&A session, Virtek Vision’s CEO, Dietmar Wennemer reveals how the company’s laser projection solutions helps rapidly improve aerospace part production.

Processes such as cutting, placement and lay-up on mould tooling can add substantial time to the production of carbon composite parts in aerospace applications, particularly when dealing with large structures such as wings.

Virtek’s Iris software platform along with the Vision Positioning System (VPS) enables operators to construct composite parts without the use of bulky physical templates that have to be manually lifted on and off the mould while ply material is fixed in place. The system projects a laser outline of the part or material to easily guide the operator.