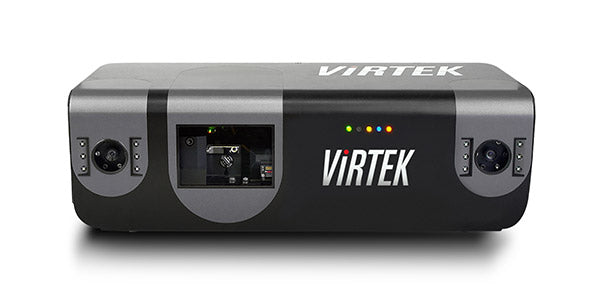

Component Placement

A clear challenge: Increase Productivity by Reducing Setup Time

At McCabe Lumber we want to be more than just a place to get materials. We want to be your project partner, offering you access to an extensive inventory backed by a knowledgeable and experienced staff who will help you find the perfect solution for your project.

"Virtek Lasers helps take the guess work out of building and gives time back to the station that would normally have been wasted measuring or over jigging to ensure the quality from one truss to the next. "

Mike Kraft, Production Manager